What are the layers in laminates composed of sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

Laminates, versatile materials composed of multiple layers, find widespread applications across various industries due to their exceptional properties. Understanding the composition and arrangement of these layers is crucial for comprehending the unique characteristics and performance of laminates.

Components of Laminate Layers

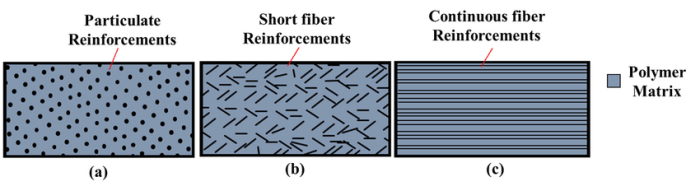

Laminates are composed of multiple layers, each with its own unique material composition and function. These layers can vary in thickness, material, and arrangement, depending on the desired properties of the final laminate.

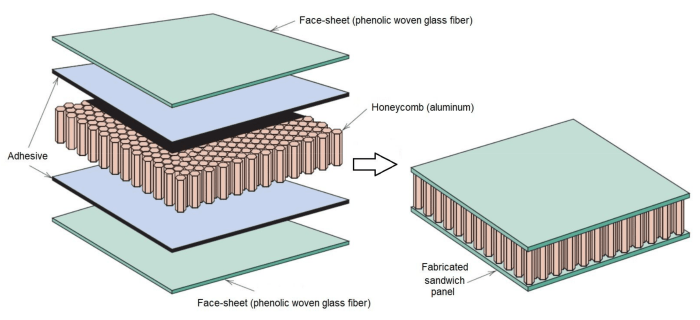

Core Layer

The core layer is the thickest layer of the laminate and provides the majority of its strength and rigidity. It is typically made of a lightweight material such as wood, particleboard, or fiberboard. The core layer can be reinforced with additional materials such as fiberglass or metal to increase its strength and durability.

Decorative Layer

The decorative layer is the top layer of the laminate and provides the desired aesthetic appearance. It is typically made of a thin layer of paper or plastic that is printed with a design or pattern. The decorative layer can be coated with a clear protective layer to protect it from wear and tear.

Overlay Layer

The overlay layer is a thin, transparent layer that is applied to the top of the decorative layer. It protects the decorative layer from scratches, stains, and other damage. The overlay layer is typically made of a durable material such as melamine or acrylic.

Backing Layer

The backing layer is the bottom layer of the laminate and provides additional stability and support. It is typically made of a thin layer of paper or plastic that is glued to the core layer. The backing layer can be coated with a moisture-resistant material to prevent the laminate from warping or delaminating.

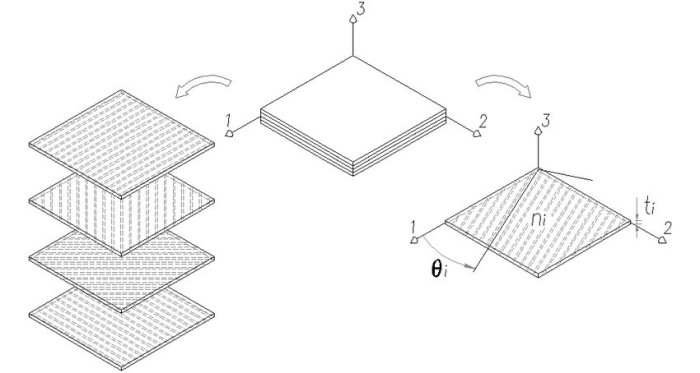

Structure and Arrangement of Layers

The layers of a laminate are typically arranged in the following sequence:

- Backing layer

- Core layer

- Decorative layer

- Overlay layer

The backing layer provides a stable base for the laminate and prevents moisture from penetrating the core layer. The core layer provides the majority of the laminate’s strength and rigidity. The decorative layer provides the desired aesthetic appearance. The overlay layer protects the decorative layer from damage.The

order and composition of the layers can be varied to achieve different properties. For example, a laminate with a thicker core layer will be stronger and more rigid than a laminate with a thinner core layer. A laminate with a thicker overlay layer will be more resistant to scratches and stains than a laminate with a thinner overlay layer.

Manufacturing Processes for Laminates

Laminates are manufactured using a variety of processes, including:

High-Pressure Laminate (HPL), What are the layers in laminates composed of

HPL is a type of laminate that is made by bonding multiple layers of paper or fabric together under high pressure and temperature. The resulting laminate is strong, durable, and resistant to wear and tear.

Low-Pressure Laminate (LPL)

LPL is a type of laminate that is made by bonding multiple layers of paper or fabric together under low pressure and temperature. The resulting laminate is less strong and durable than HPL, but it is also less expensive.

Direct Pressure Laminate (DPL)

DPL is a type of laminate that is made by bonding a decorative layer to a core layer using a direct pressure process. The resulting laminate is strong, durable, and has a smooth, seamless finish.

Post-Forming Laminate (PFL)

PFL is a type of laminate that is made by bonding a decorative layer to a core layer using a post-forming process. The resulting laminate can be bent or curved to create complex shapes.

Applications and Properties of Laminates: What Are The Layers In Laminates Composed Of

Laminates are used in a wide variety of applications, including:

Countertops

Laminates are a popular choice for countertops because they are durable, easy to clean, and available in a wide variety of colors and patterns.

Flooring

Laminates are also a popular choice for flooring because they are durable, easy to install, and resistant to wear and tear.

Furniture

Laminates are used in a variety of furniture applications, including cabinets, desks, and tables. Laminates are durable, easy to clean, and can be made to look like wood or other materials.

Automotive

Laminates are used in a variety of automotive applications, including dashboards, door panels, and headliners. Laminates are durable, easy to clean, and can be made to look like a variety of materials.

Environmental Considerations

Laminates are a durable and long-lasting material, which can help to reduce waste. However, the production of laminates can also have a negative impact on the environment.The production of laminates requires the use of fossil fuels, which can contribute to greenhouse gas emissions.

The use of certain chemicals in the production of laminates can also pollute the environment.There are a number of ways to reduce the environmental impact of laminates. These include:

Using sustainable materials

Laminates can be made from a variety of sustainable materials, such as recycled paper and wood.

Using eco-friendly manufacturing processes

Laminates can be manufactured using eco-friendly manufacturing processes, such as low-pressure lamination and water-based adhesives.

Recycling laminates

Laminates can be recycled at the end of their useful life.

FAQ Explained

What is the primary function of the core layer in a laminate?

The core layer provides structural support and stability to the laminate, ensuring its rigidity and overall strength.

How does the thickness of the overlay layer impact the durability of a laminate?

A thicker overlay layer enhances the laminate’s resistance to wear, abrasion, and chemicals, extending its lifespan and maintaining its aesthetic appeal.

What are the advantages of using environmentally friendly materials in laminate production?

Sustainable materials reduce the environmental footprint of laminate manufacturing, promoting resource conservation and minimizing waste.